Valves are essential control elements in fluid systems‚ regulating flow‚ pressure‚ and direction. They are crucial for efficient operation across various industries‚ ensuring safety and precision.

What are Valves?

Valves are devices used to regulate‚ control‚ or direct the flow of fluids (liquids‚ gases‚ or slurries) in a system. They serve as essential components in various industries‚ ensuring precise operation and safety. Valves operate by opening‚ closing‚ or partially obstructing passageways to manage pressure‚ flow rate‚ and direction. Their design varies widely‚ from simple on/off controls to complex flow modulation systems. Integral to valve function are valve guides‚ which ensure proper alignment and smooth movement of internal components. Together‚ valves and guides play a critical role in maintaining efficiency and reliability in industrial and mechanical systems.

History and Evolution of Valves

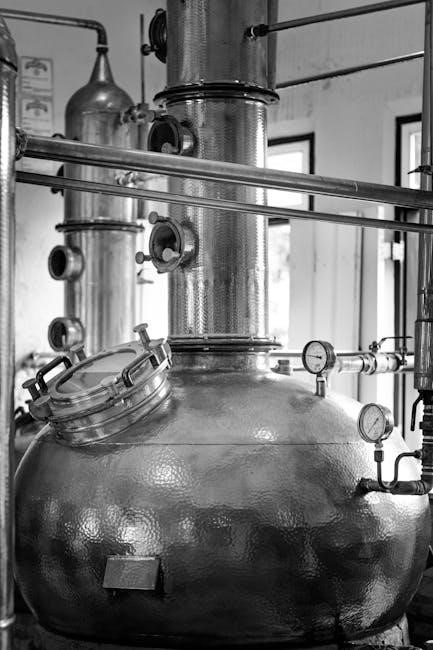

The history of valves dates back to ancient civilizations‚ where rudimentary devices controlled water flow in aqueducts and irrigation systems. Over centuries‚ valve design evolved‚ with significant advancements during the Industrial Revolution. The development of steam engines in the 18th century necessitated precise control mechanisms‚ leading to the creation of more sophisticated valve types. In the 20th century‚ materials like stainless steel and plastics enabled valves to withstand extreme conditions. Modern innovations include smart valves with automation and IoT integration‚ enhancing efficiency and safety. Valve guides‚ crucial for smooth operation‚ have also evolved‚ with improved materials and designs ensuring durability and reliability in diverse applications.

Types of Valves

Valves are classified into various types based on their operation and application. Common types include globe‚ gate‚ butterfly‚ ball‚ and check valves‚ each serving unique purposes in fluid control.

Globe Valves

Globe valves are a type of valve characterized by their spherical body and adjustable disc or plug. They are widely used for precise flow control‚ throttling‚ and isolation in pipelines. Designed to regulate fluid flow by adjusting the position of the disc‚ globe valves are ideal for applications requiring frequent operation. They are commonly used in high-pressure and high-temperature environments due to their robust construction. Globe valves are available in various configurations‚ including rising stem and rotating stem designs‚ making them versatile for different industrial needs. Their ability to provide tight shutoff and leak resistance makes them a preferred choice in systems requiring reliable performance and durability.

Gate Valves

Gate valves are designed for on/off fluid flow control‚ featuring a flat gate that moves perpendicular to the flow direction. They are commonly used in applications requiring minimal pressure drop and tight shutoff. The gate valve operates by raising or lowering the gate‚ which provides a reliable seal when fully closed. Available in various materials such as cast iron‚ stainless steel‚ and bronze‚ gate valves are suitable for water supply‚ oil and gas‚ and chemical processing industries. They are typically not recommended for throttling or frequent operation‚ as this can lead to wear and tear. Gate valves are known for their simplicity‚ durability‚ and effectiveness in straightforward flow control scenarios.

Butterfly Valves

Butterfly valves are versatile flow control devices characterized by a rotating disc that pivots to regulate fluid flow. They are lightweight‚ compact‚ and easy to maintain‚ making them ideal for applications requiring minimal space. These valves are commonly used in HVAC systems‚ water supply networks‚ and chemical plants. Butterfly valves are suitable for both on/off and throttling operations‚ offering precise control over flow rates. Available in materials like stainless steel‚ cast iron‚ and PVC‚ they are durable and adaptable to various environments. Their design ensures low pressure drop and efficient operation‚ making them a preferred choice for industries needing reliable and cost-effective solutions.

Ball Valves

Ball valves are durable and reliable devices designed to control fluid flow using a spherical ball with a bored center. They are widely used in oil‚ gas‚ and chemical industries due to their excellent sealing properties and ease of operation. The valve operates by rotating the ball‚ allowing or blocking fluid flow. Key components include the ball‚ stem‚ and seats‚ which ensure tight shutoff and minimal leakage. Ball valves are available in various materials‚ such as stainless steel‚ brass‚ and PVC‚ making them suitable for diverse applications. They are ideal for both on/off and throttling operations‚ offering precise control and low pressure drop. Their compact design and minimal maintenance requirements make them a popular choice across industries.

Check Valves

Check valves are essential components designed to prevent backflow in fluid systems by allowing flow in one direction only. They operate automatically‚ relying on fluid pressure to open or close the valve. The valve features a movable element‚ such as a disc or ball‚ that lifts to permit forward flow and shuts to block reverse flow. Common types include swing‚ spring-loaded‚ and piston-style check valves. They are critical for maintaining system safety‚ efficiency‚ and preventing potential damage from backflow. Check valves are widely used in industries like oil and gas‚ water treatment‚ and HVAC systems. Their reliability and low maintenance make them a fundamental part of fluid control systems.

How Valves Work

Valves regulate the flow of fluids by opening‚ closing‚ or partially obstructing passageways. They operate using actuators‚ positioners‚ and internal mechanisms to control pressure and directional flow.

Operating Mechanism of Valves

Valves operate through a combination of mechanical and fluid dynamic principles. The mechanism involves a movable component‚ such as a disc‚ ball‚ or gate‚ which regulates fluid flow. Actuators‚ powered by manual‚ pneumatic‚ hydraulic‚ or electric forces‚ control the valve’s motion. Linear or rotary movement is applied to the stem‚ which transmits force to the valve’s closing element. The interaction between the seat and the disc determines flow control‚ enabling precise regulation of pressure and volume. Valve guides ensure proper alignment and smooth operation‚ while seals prevent leakage. This mechanism allows valves to function reliably in diverse applications‚ from throttling to on/off control.

Key Components of Valves

Valves consist of several critical components essential for their operation. The valve body houses the internal parts and connects to the piping system. The bonnet covers the valve’s operating mechanism‚ protecting it from external factors. The disc or plug regulates fluid flow by opening or closing against the seat. The stem connects the disc to the actuator‚ transmitting motion. Valve guides ensure proper alignment and smooth movement of the stem. The actuator‚ whether manual or automated‚ provides the force to open or close the valve. These components work together to control flow‚ pressure‚ and directional changes in fluid systems.

Flow Control Principles

Flow control in valves is achieved through precise regulation of fluid movement. The primary mechanisms include throttling‚ where the valve restricts flow by partially opening‚ and on/off control‚ which completely stops or allows fluid flow. Valves also control flow direction using designs like three-way or four-way valves. The orifice size and valve trim (e.g.‚ seat‚ disc) determine the flow rate and pressure drop. Actuators and positioners fine-tune these adjustments‚ enabling automation; Proper sizing and type selection ensure efficient flow regulation‚ while minimizing energy loss and wear. These principles are crucial for maintaining system performance and reliability across various applications.

Applications of Valves

Valves are essential in various industries‚ controlling fluid flow‚ pressure‚ and direction. They are critical in oil and gas‚ chemical plants‚ power generation‚ and HVAC systems‚ ensuring efficiency and safety.

Valves in Oil and Gas Industry

Valves play a crucial role in the oil and gas industry‚ ensuring the safe and efficient flow of fluids across various operations. From extraction to refining‚ they regulate pressure‚ prevent leaks‚ and control the direction of fluids. Ball valves‚ gate valves‚ and choke valves are commonly used in upstream‚ midstream‚ and downstream processes. These valves must withstand harsh environments‚ including high temperatures and corrosive substances‚ making materials like stainless steel and titanium essential. Actuators and control systems are often integrated to automate valve operations‚ enhancing precision and safety. Proper valve functionality is vital for maintaining process integrity‚ preventing accidents‚ and optimizing production efficiency in the oil and gas sector.

Valves in Chemical Processing

Valves are essential in chemical processing for controlling the flow of corrosive‚ toxic‚ and high-temperature fluids. They ensure precise regulation‚ preventing contamination and maintaining process safety. Ball valves‚ butterfly valves‚ and diaphragm valves are widely used due to their durability and sealing capabilities. Materials like stainless steel‚ Hastelloy‚ and PTFE-lined valves are chosen for their resistance to harsh chemicals. Actuated valves enable remote operation‚ enhancing safety and efficiency. Proper valve selection and maintenance are critical to prevent leaks and downtime‚ ensuring compliance with safety standards and environmental regulations. Their reliability directly impacts the efficiency and safety of chemical manufacturing processes.

Valves in Power Generation

Valves play a critical role in power generation‚ ensuring efficient and safe operation of systems. They regulate the flow of steam‚ water‚ and gases in power plants‚ maintaining optimal pressure and temperature. Globe valves and gate valves are commonly used for precise control‚ while butterfly valves are preferred for large-scale flow management. In nuclear plants‚ specialized valves ensure safety by preventing radioactive leaks. Valves also manage cooling systems‚ preventing overheating and maintaining equipment longevity. Their reliability is crucial for consistent energy production and environmental compliance. Regular maintenance and advanced materials‚ like stainless steel‚ ensure durability in harsh environments. Proper valve operation is vital for power generation efficiency and safety standards.

Valves in HVAC Systems

Valves are essential in HVAC systems for controlling the flow of water‚ steam‚ and refrigerants. They ensure efficient temperature regulation and energy management. Globe valves and ball valves are commonly used for precise flow control‚ while butterfly valves are preferred for larger systems. Thermostatic valves adjust water flow based on temperature‚ maintaining consistent heating or cooling. Actuated valves enable remote operation‚ improving system automation. Proper valve sizing and material selection are crucial to handle varying pressures and temperatures. Regular maintenance ensures optimal performance‚ preventing leaks and energy losses. Valves play a vital role in balancing HVAC systems‚ ensuring comfort and energy efficiency in residential and commercial settings.

Maintenance and Troubleshooting

Regular inspections and cleaning are vital for valve longevity. Lubricate moving parts and check for wear. Address leaks and blockages promptly. Troubleshooting often involves diagnosing common issues.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for valve and guide longevity. Always follow manufacturer guidelines during installation to ensure correct alignment and functionality. Use appropriate tools and materials‚ such as compatible lubricants‚ to prevent damage. Regular inspections should be conducted to identify and address potential issues early. Clean the valve and guides thoroughly‚ removing any debris or residue that could impede performance. Schedule periodic maintenance to replace worn-out components and ensure optimal operation. Proper training for maintenance personnel is essential to handle tasks effectively. Neglecting these steps can lead to premature wear and unexpected failures. By adhering to these tips‚ you can significantly enhance the efficiency and lifespan of your valves and guides.

Common Issues in Valve Operation

Valves often face operational challenges that can disrupt flow control and system efficiency. Leakage is a prevalent issue‚ typically caused by worn-out seats‚ damaged gaskets‚ or improper sealing. Sticking or frozen valves can occur due to corrosion‚ mineral buildup‚ or debris accumulation. Actuator malfunctions‚ such as faulty solenoids or insufficient power supply‚ can prevent proper valve opening or closing. Pressure imbalances and cavitation are additional concerns‚ leading to valve instability or damage. Regular cleaning and lubrication of moving parts can mitigate these problems‚ while replacing worn components ensures smooth operation. Addressing these issues promptly is essential to maintain system performance and reliability.

Troubleshooting Valve Problems

Troubleshooting valve issues requires a systematic approach to identify and resolve malfunctions. Start by identifying symptoms such as leakage‚ unusual noise‚ or failure to open/close fully. Inspect the valve for visible damage‚ wear‚ or corrosion. Check for proper alignment and connection integrity. Clean or replace clogged filters and screens to ensure unobstructed flow. For actuator-related problems‚ verify power supply and signal accuracy. Lubricate moving parts if sticking occurs. Replace worn or damaged components like seals‚ gaskets‚ or seats. After repairs‚ test the valve under operating conditions to ensure proper function. Regular maintenance and timely intervention prevent recurring issues and extend valve lifespan.

Valve Guides

Valve guides are critical components ensuring proper alignment and smooth operation of moving parts within valves‚ maintaining optimal performance and durability over time in various applications.

What are Valve Guides?

Valve guides are essential components designed to ensure the proper alignment and movement of a valve’s operating stem or disc. They play a crucial role in maintaining the integrity of the valve’s operation by preventing wear and tear from misalignment. These guides are typically integrated into the valve’s structure and work in conjunction with other key components‚ such as the valve seat and stem‚ to ensure smooth and precise movement. By providing a stable pathway for the valve’s moving parts‚ guides contribute to efficient flow control‚ reduced leakage‚ and extended service life. They are a fundamental element in maintaining optimal valve performance across various industries.

Importance of Valve Guides

Valve guides are crucial for ensuring the efficient‚ reliable‚ and safe operation of valves. They prevent misalignment and wear on moving parts‚ enhancing longevity and reducing maintenance needs. By maintaining precise control over fluid or gas flow‚ they contribute to operational efficiency and consistency. In industrial settings‚ proper guides prevent leaks and potential safety hazards‚ which is vital in sectors like oil and gas‚ chemical processing‚ and power generation. They also play a role in environmental safety by minimizing leaks that could lead to resource wastage or ecological damage. Overall‚ valve guides are essential for optimal valve performance‚ safety‚ and environmental protection.

Types of Valve Guides

Valve guides are categorized into distinct types based on their design and functionality. Integral guides are permanently built into the valve‚ offering simplicity but requiring full replacement if worn. Renewable guides‚ in contrast‚ can be replaced‚ making them ideal for high-wear applications. Pilot guides are specialized for precise alignment in specific valve types. Each design addresses unique operational demands‚ ensuring optimal performance and durability. Selecting the right guide type is vital for minimizing downtime and extending valve lifespan‚ particularly in industrial and mechanical systems where reliability is paramount. Proper guide selection ensures efficient operation and reduces long-term maintenance costs.

Materials Used for Valve Guides

Valve guides are typically made from durable materials to ensure longevity and performance. Common materials include bronze‚ brass‚ and stainless steel‚ which offer excellent resistance to wear and corrosion. In high-temperature applications‚ materials like Stellite or Nimonic are used for their heat-resistant properties. For extreme conditions‚ ceramic or hardened steel guides may be employed. Non-metallic materials‚ such as PTFE‚ are sometimes used in specialized applications requiring chemical resistance. The choice of material depends on the operating conditions‚ ensuring optimal performance and minimizing wear. Proper material selection enhances valve reliability and lifespan‚ making it a critical factor in valve design and operation.

Replacement and Refurbishment

Valve guides may require replacement or refurbishment due to wear over time. Replacement involves removing the old guide and installing a new one‚ ensuring precise alignment and fit. Refurbishment often includes machining or resurfacing the existing guide to restore its functionality. Regular inspection is crucial to determine if replacement or refurbishment is needed. Proper tools and techniques are essential to avoid damaging the valve during the process. Replacement and refurbishment not only extend the valve’s lifespan but also maintain optimal performance. These procedures are cost-effective compared to replacing the entire valve assembly. Regular maintenance ensures valves operate efficiently and reliably over time.

Future Trends in Valve Technology

Future trends in valve technology emphasize smart solutions‚ with IoT-enabled valves becoming prevalent‚ offering real-time monitoring and automation. AI-driven predictive maintenance is gaining traction‚ optimizing valve performance. Advanced materials like graphene and ceramic coatings are being explored for durability and corrosion resistance. Sustainability is a key focus‚ with eco-friendly valve designs minimizing environmental impact. 3D printing is revolutionizing valve manufacturing‚ enabling rapid prototyping and customization. Energy-efficient valves are being prioritized to reduce power consumption. These advancements aim to enhance reliability‚ efficiency‚ and adaptability‚ ensuring valves remain central to modern industrial systems. The integration of these technologies positions valves as critical components in future-proof infrastructure.